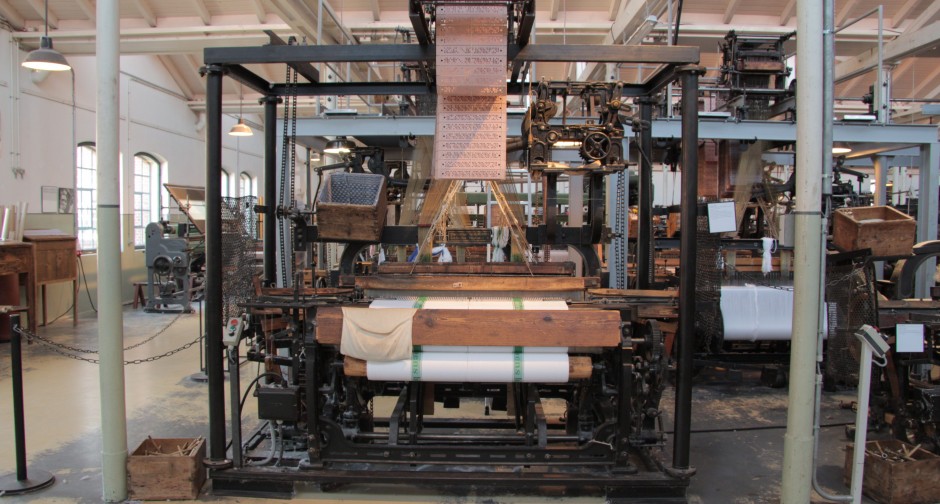

Weaving machine

The electric linen weaving machine (dobby and jacquard machine) of the type G. A. Roscher from the 1920s was used to produce linen cloth with patterns. Originally it was in operation in the weaving mill of the Brothers Büning in Borken (Germany, North Rhine-Westphalia). Today it is located at the LWL-Industrial Museum Bocholt Textile Factory and it is used for demonstration purposes.

The sound of this machine emanates from its mechanism: the up and down motion of the „shafts“, the „shuttles“ moving back and forth, the hammering of the „weaving comb“ and the changing of the jacquard punch card are the essential sounds heard here.

The „shafts“are frames on the front side of the weaving machine each of which moves a number of the warp threads (which are stretched lengthwise in a loom) up and down.

By doing so they open a gap between the warp threads, through which a shuttle connected to a weft thread (which runs crosswise to the warp threads attached to the loom) is shot. After every weft insertion a weaving comb beats the weft thread down onto the cloth so that it remains tight.

A punch card is a mechanical data medium made of punched cardboard using a binary system: “hole” and “no hole”. If the needle hits the cardboard (no hole), the thread is lifted, but when it encounters a hole, the thread is lowered and the cloth is penetrated. The manner in which the cards are punched is analogous to the weaving pattern. This punch card technique makes it possible to weave the same patterns over and over again.

Sound recordist: Konrad Gutkowski/Julian Blaschke

Photographer: Konrad Gutkowski/Julian Blaschke

Video recordist: Konrad Gutkowski/Julian Blaschke

Specs:

Filesize:

Duration:

Channels:

21.2 MB

2 min 0 s

2 (Stereo)

Bit rate:

Bit depth:

Level:

1411 kb/s

16 bit

94,8 dB

Recorded on March 20, 2014

LWL-Industriemuseum TextilWerk Bocholt

Bocholt, GERMANY

Creative Commons License