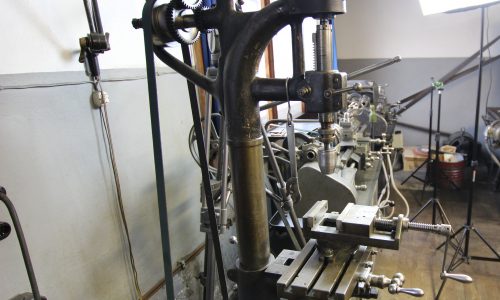

Milling – two heads

The sound of milling with two heads.

This machine is fitted with two horizontal milling heads thus allowing a simultaneous processing of both lateral surfaces. This is a double-spindle CNC-machine, a KEKEISEN D-PBF 4500, with a table length of 4500mm, width 600mm. The milling head has an output of 2 x 40kW. Manufactured in 2006.

Milling is the process of cutting away material by feeding the steel past a rotary cutter. The feeding motion can be linear or rotary. Although the milling process is most commonly used on flat surfaces, special cutters also enable the processing of curved surfaces.

Metal Ravne is the legal successor to Železarna Ravne. The company's range includes a steel plant programme, which starts the production of all their rolled and forged products. Due to technological modernisation over recent years, the company has all the most important machinery for the production of high-quality steel, including a 45t UHP electric arc furnace, a vacuum ladle furnace and a state-of-the-art ‘teeming pit’ for high-class conventional ingots. Their range of products includes ingots, billets with rounded edges and wide flats, with round, flat and square sections, forged bars, machined forgings, discs, bushes, etc.

Sound recordist: Dušan Oblak

Photographer: Veronika Štampfl

Video recordist: Barbara Grilc

Specs:

Filesize:

Duration:

Channels:

13.4 MB

1 min 10 s

2 (Stereo)

Bit rate:

Bit depth:

Level:

1536 kb/s

16 bit

84 dB

Recorded on December 11, 2014

Metal Ravne d.o.o.

Ravne na Koroškem, SLOVENIA

Creative Commons License